Description

|

|

|

|

|

||

|---|---|---|---|---|---|---|

| UY128 |  |

Normal standard: 5.6 Optional by ordering 4.0 / 4.8 / 6.4 |

0.3~4.5 | 4500 | L1200 W1200 H1670 |

180/240 |

|

Capability of Output

|

80~120 pcs/ hour

|

|---|---|

|

Power supply

|

AC 220V 50/60Hz

|

|

Air Pressure

|

4 bar

|

|

Air Consumption

|

190 L / min

|

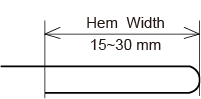

Circumference of T-shirt bottom(Flattened)

380-900 mm

Folding center distance

|

Machine Head

|

Normal standard: Top feed cylinder bed type C007KP-W812A-356/CRL/UTP

|

|---|---|

|

Standard seam guide function

|

It can be used to sew both front and back stitching positions

(with true back stitch function) |

|

Sweep the line device

|

Standard configuration: blowing device Optional Configuration:Electromagnet wire hooking device

|

|

IOT interconnection (Please select it when ordering)

|

|

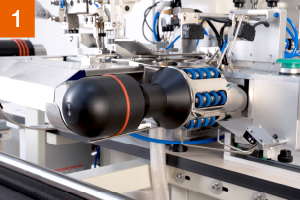

The patented guide wheel simulates operator’s gestures, it makes the machine operating smoothly during the sewing, and applicable for more kinds of fabric.

nted air-blowing reverse stitching functionmakes side seams reverse stitching in the same direction.

The start and end stitches are perfectly aligned.

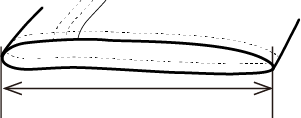

The equipment comes with an automatic adjustment function of clothes size, which avoids confusion in sewing caused by mixed sizes in production.

The sewing range of 38-90 cm can sew sizes in between XS to 5XL.

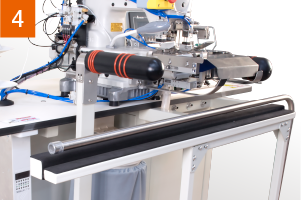

Fully automatic hemming is suitable for tubular materials or materials with overlock seams.

It can be the first stage or last stage of production process.

High-speed sewing with 100% cotton thread.

Machine operators can handle more than one machine simultaneously. Reducing the difficulty of manual sewing and standardizing production, without the need for skilled workers to operate.