Description

| Sewing speed | Max. 4,200sti/min, Normal 3,600sti/min |

| Needle bar stroke | 34.6mm |

| Size of cloth cutting knife | 6.4~31.8mm (1/4″~1-1/4″) |

| Bartacking width | Max. 5.0mm |

| Buttonhole length | Max. 41mm (optional: 120mm) LBHS-1795: 120mm |

| Precision of needle throwing mechanism | 0.05mm |

| Needle thread tension | Active tension (electronic thread tension control system) |

| Number of stitches | Automatically computed from the size of the buttonhole and stitch pitch |

| Needle | DP×5 (#11J) #11J~#14J |

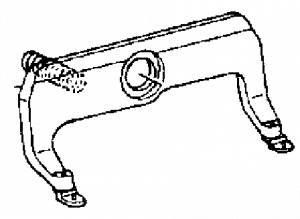

| Hook | DP type, full-rotary hook |

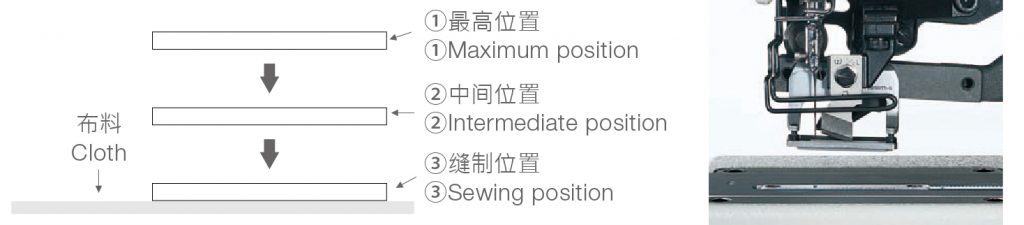

| Lift of the work clamp | 14mm (17mm by the reverse-rotation needle-up function) |

| Auto-lifter | Provided as standard (stepping motor type) |

| Needle throwing system | Stepping motor |

| Cloth feeding system | Intermittent feed by stepping motor |

| Cloth cutting knife system | By double-acting solenoid |

| Number of standard patterns | 30 patterns |

| Number of patterns that can be input | Max. 99 patterns |

| Bobbin thread winder | Built-in the machine head |

| Machine head drive system | Compact AC servomotor (direct-drive system) |

| Power requirement/ Power consumption | Single-phase 220V, 230V, 240V・3-phase 200~240V/600VA |

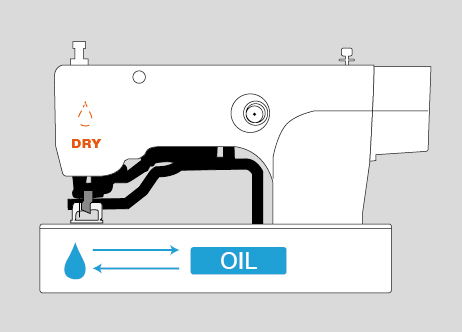

| Lubrication | Only the hook section needs a minute-quantity lubrication. |

| Lubricating oil | Hook: New Defrix Oil No.1 (equivalent to ISO VG7) |

| Total weight | 112kg |

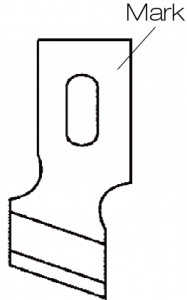

| Knife size | Cloth cutting knife

|

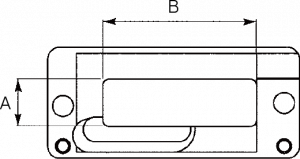

Cloth cutting knife , Work clamp

|

Work clamp foot |

||||||||||||

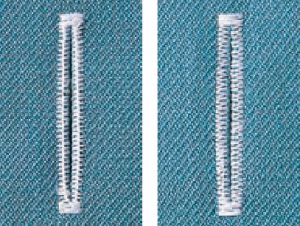

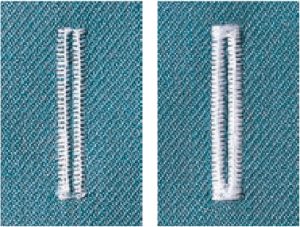

| For stitch width 5mm | For stitch width 6mm |

||||||||||||||

| LBHS-1790S (standard) |

LBHS-1792K (for knits) |

LBHS-1795A (standard) |

LBHS-1790S (standard) |

||||||||||||

| Part No. | Mark | Part No. (Length of cloth cutting knife) |

Part No. |

1790 S |

1792 K |

Part No. |

1790 S |

||||||||

| 6.4mm (1/4″) | BL724AJK | A | P570CJK (6.4×19.1mm) <1> (4×25mm) |

◎ | P576JK (6.4×19.1mm) <1> (4×25mm) |

P575AJK (5×120mm) |

◎ | P573JK (6.4×31.8mm) <3> (6×41mm) |

P570CJK-A <1> |

◎ | P574JK | ◎ | |||

| 9.5mm (3/8″) | BL724BJK | △ | B | ||||||||||||

| 11.1mm (7/16″) | BL724CJK | C | |||||||||||||

| 12.7mm (1/2″) | BL724DJK | ◎ | D | ||||||||||||

| 14.3mm (9/16″) | BL724EJK | E | |||||||||||||

| 15.9mm (5/8″) | BL724FJK | △ | F | ||||||||||||

| 17.5mm (11/16″) | BL724GJK | G | |||||||||||||

| 19.1mm (3/4″) | BL724HJK | H | |||||||||||||

| 22.2mm (7/8″) | BL724IJK | I | P571CJK (6.4×25.4mm) <2> (5×35mm) |

P572JK (6.4×25.4mm) <2> (5×35mm) |

◎ | P572JK-A <2> |

◎ | ||||||||

| 25.4mm (1″) | BL724JJK | △ | J | ||||||||||||

| 31.8mm (1-1/4″) | BL724KJK | K | P574CJK (6.4×31.8mm) <3> (5×41mm) |

P577JK (6.4×31.8mm) <3> (5×41mm) |

|||||||||||